Are you a manufacturer or importer of medical devices and do you do business in the EU/EEA? Then make sure your products meet legal requirements in the area of safety and health.

The MDD 93 42 EEC directive stipulates that medical devices and accessories may only be authorised and marketed in the European market if they have CE marking. For this, the manufacturer must carry out a conformity assessment procedure (or have it carried out). Baat Medical has managed to do conformity assessment for a range of products, including joint implants, spinal implants, orthoses, and many more.

Article 1(2) of the Directive defines a medical device as “any instrument, apparatus, appliance, material, software or other article intended by the manufacturer to be used in human beings for the detection, treatment, alleviation or prevention of disease, injury or disability. Devices for the control of fertilization and devices for research into (or modification of) anatomical and physiological processes are also covered.

On May 26, 2021, Directive 93/42/EEC will be repealed and succeeded by Regulation (EU) 2017/745.

Medical devices for in vitro diagnostics and active implantable devices are covered by other, separate CE directives.

The directive does not apply – with some exceptions – to:

Medical devices must meet certain essential health and safety requirements. These requirements are described in Annex I of the directive. The requirements cover the technical and constructive safety, sterility, bio-compatibility and any measurement functions and energy sources of the devices. The Annex also provides instructions for indications on product labels and instructions for use.

In general, medical devices meet the requirements of the directive if they comply fully with the applicable harmonized standards for these products. In the Netherlands, you can request the relevant standards sheets from standardization institute NEN.

In the Netherlands, manufacturers of medical devices of risk class I must register their products via Farmatec’s online registration system (Notis) before placing them on the Dutch or European market. Farmatec is part of CIBG, an executive organisation of the Ministry of Health, Welfare and Sport (VWS).

Determine precisely the procedure by which you must assess the conformity of your product. This differs per risk class. Medical devices are divided into 4 risk classes:

The classification rules for these can be found in Annex IX of the directive. The assessment procedures are described in general terms in Article 11 and in more detail in Annexes II to VII. For each class of risk you can choose from 2 or more possibilities for assessing your product against the essential requirements.

You must always involve a notified body in the assessment of devices in classes IIa, IIb and III. For Class I devices, involvement of a notified body is only required if your products have a measuring function or are marketed in a sterile condition.

After inspection, the notified body issues an inspection report or inspection certificate to the manufacturer.

As the manufacturer, you must prepare technical documentation. To do this, you use the instructions in the annexes (II to VII) to the directive that apply to your product and risk class. You must keep this documentation at the disposal of national market surveillance authorities in the EU/EEA countries for at least 5 years, who may request access to it. The documentation must enable market surveillance authorities to assess whether your product complies with the requirements of the Directive.

Before placing your product on the market, as a medical device manufacturer, you must prepare and sign an EC Declaration of Conformity. You add this declaration to your technical documentation. With this act you take full responsibility for the conformity of your product to the requirements of the directive.

The procedures for this declaration are detailed in Article 11, Annex II and Annexes V to VIII. You should retain the declaration for at least 5 years from the date the device was placed on the market.

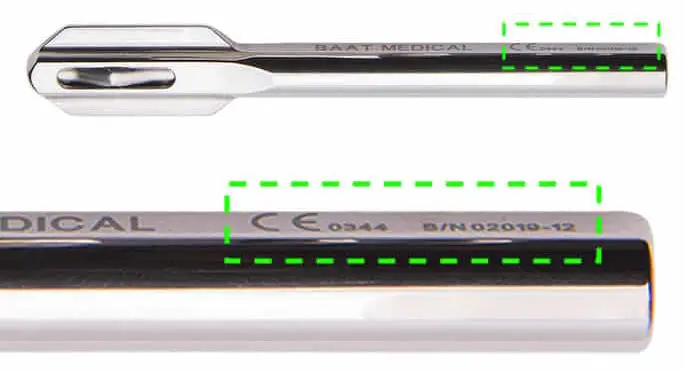

If the devices meet all the essential requirements, affix the CE marking. Instructions for this can be found in Article 17 and Annex XII of the directive. Did you involve a notified body in the conformity assessment? If so, you must also state their identification number with the CE marking.

The CE marking is not required for devices that you make on prescription for an individual patient or that are intended for clinical research.

When you transform your idea into an approved biomedical device design you will encounter hurdles. BAAT is successfully guiding customers to overcome these hurdles since 1999. Use this experience to navigate the intricacies of your medical device and development and get your product approved for market introduction.